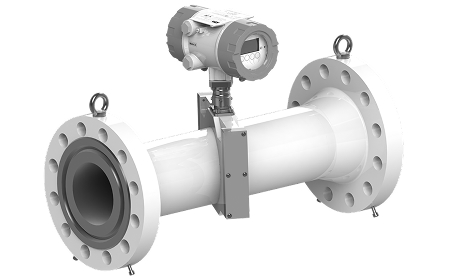

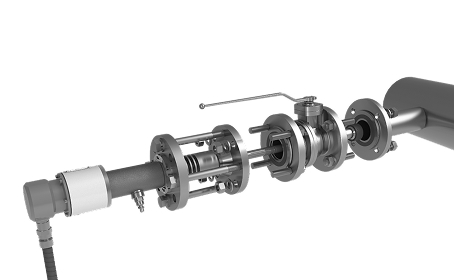

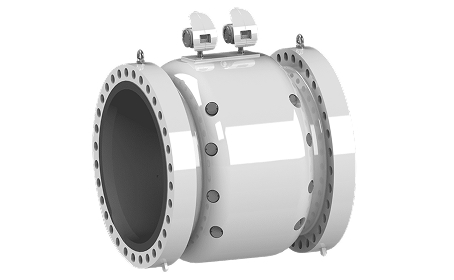

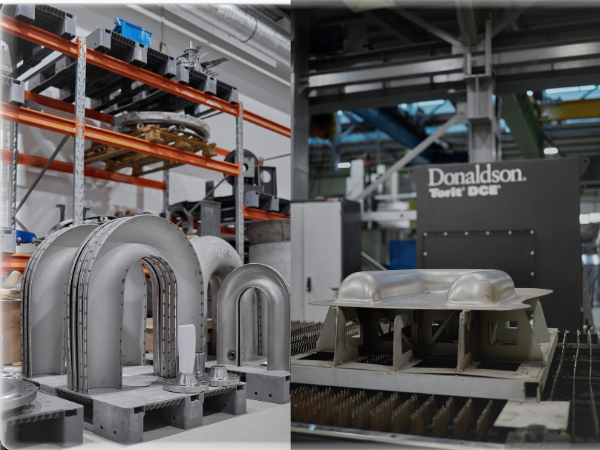

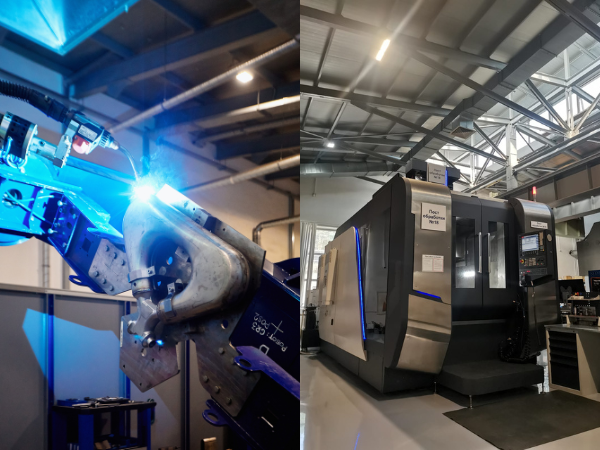

Our design bureau specializes in the development and production of high-tech equipment, in particular industrial gas and liquid flow meters

All projects

We hold patents, proprietary developments, and extensive engineering expertise in this field.

We propose considering the possibility of investing in the establishment of a manufacturing plant for such devices within your country.

We ensure technological independence and import substitution in a strategically important industry.

Partnership and investment opportunity in a manufacturing plant that can be built in your country to supply the above-mentioned gas and liquid metering and flow measurement devices for enterprises in the oil and gas, chemical, food, pharmaceutical, and energy sectors, both domestically and for export.

The investment will entail not only equity in the enterprise but also technology transfer.

We are ready to provide detailed project documentation, financial models, and technical presentations. No one else in the world can offer you such a unique opportunity.