Completed projects

Software

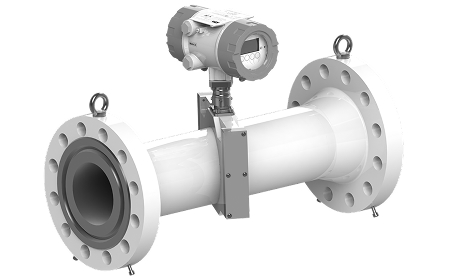

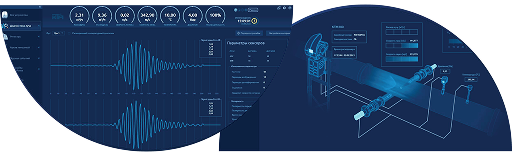

KTM Smart Stream

Software application methods

- collecting information from flow meters;

- process parameter control;

- status monitoring and remote control of metering devices;

- notifying the user about the emergency situations;

- maintaining databases of measured values.

350 000 RUB

VAT free

non-exclusive version

non-exclusive version

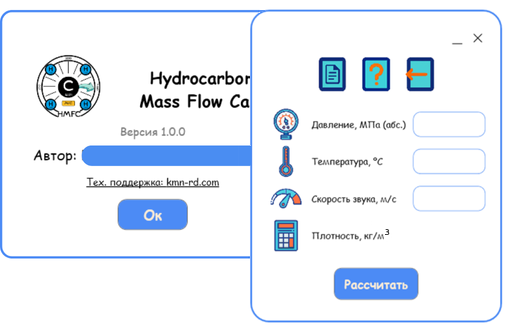

Software

Hydrocarbon Mass Flow Calc (HMFC)

Software Application Methods

- The software is intended for calculating the density of hydrocarbon gas (natural gas consisting primarily of saturated hydrocarbons CnH2n+2 from C1 to C8, with organic impurities and inert gases content not exceeding 10% by molar fraction), provided it is in a single-phase state

- The software outputs the calculated density value (kg/m3) of hydrocarbon gas based on the available input parameters:

1) sound velocity, m/s;

2) pressure, MPa;

3) temperature, °C.

280 000 RUB

VAT free

non-exclusive version

non-exclusive version